Meuble de cuisine Sous évier HELIA Gris 2 portes lessiviel-poubelle coulissante L100 x H70 x P58 cm - Oskab

Kleankin Meuble sous lavabo meuble lave-mains avec placard étagère réglabe 60 x 30 x 60 cm blanc gris-AOSOM.fr

)

Autres accessoires de décoration GENERIQUE POP Meuble sous-évier 80 cm - Gris Haute Brillance | Darty

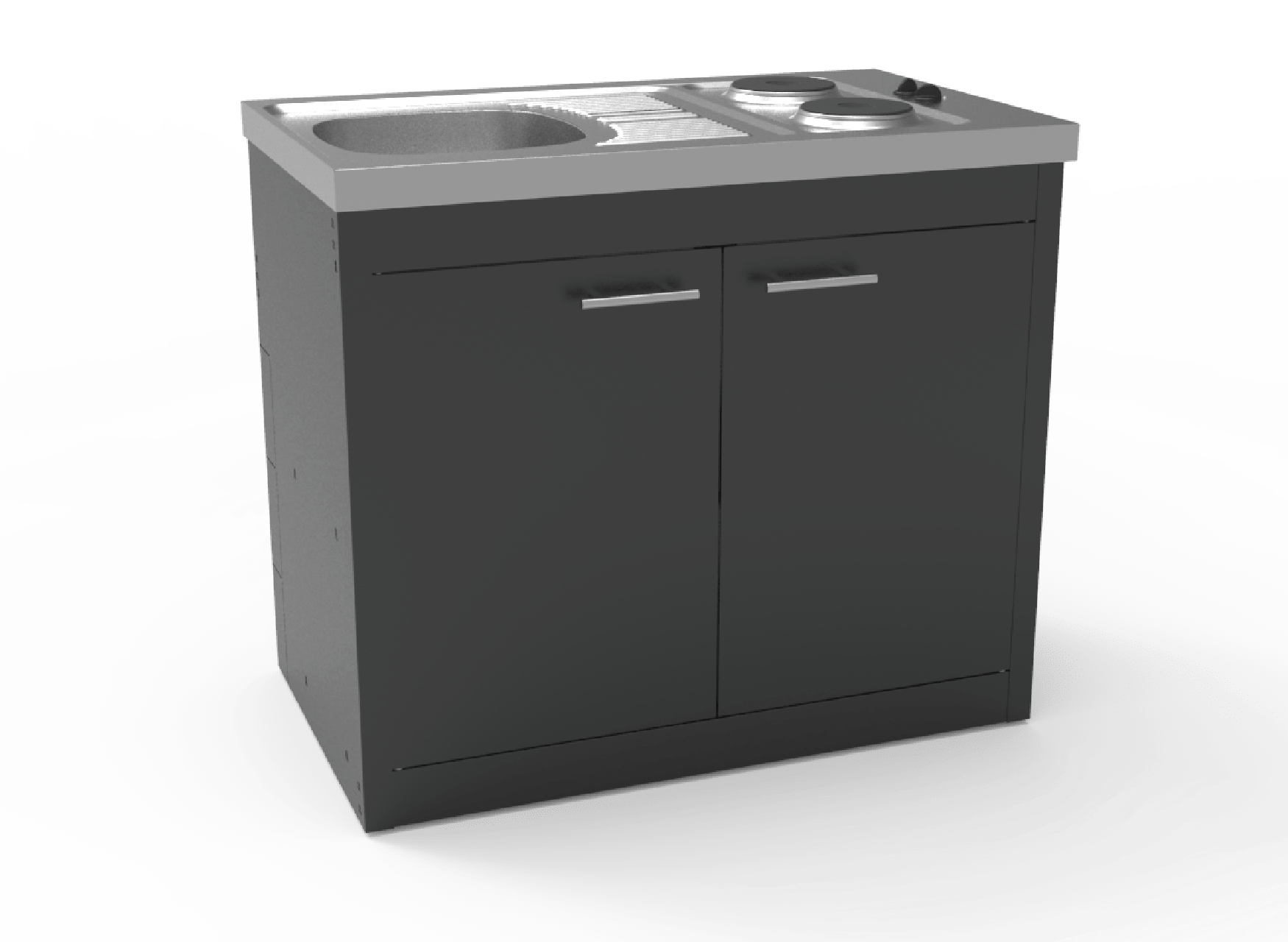

Meuble de cuisine bas - OXANE - 120cm - Gris - Laqué - Idéal pour évier double bacs - Cdiscount Maison

Berlioz Creations CE8BG Meuble Bas de Cuisine sous Evier Gris Haute Brillance 80 x 52 x 83 cm, Fabrication 100% française : Amazon.fr: Cuisine et Maison

kleankin Meuble sous lavabo meuble sous évier placard 2 portes avec étagère 60 x 30 x 60 cm gris blanc | Aosom France